Do you not have the Username and Password to access the Order Area?

Do you wish to place an order?

A correct installation of hydraulic hose assemblies is essential to ensure the safety, efficiency, and long service life of any hydraulic system. Below are the key technical recommendations, organized by area of concern, with practical examples and reference images.

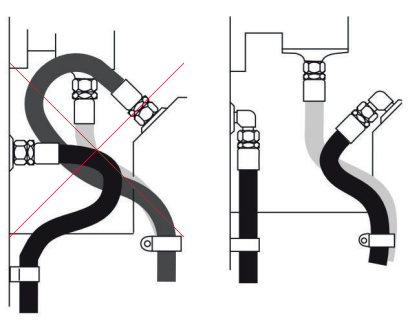

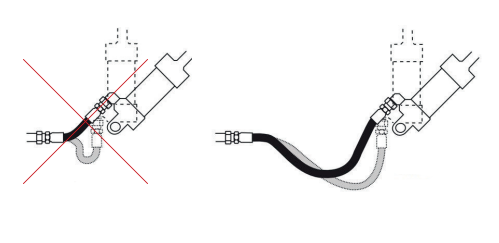

Hoses must be routed in a way that avoids contact with abrasive surfaces or moving parts during installation.

Using correctly sized clamps is recommended: oversized clamps allow hose movement, leading to premature wear.

Excessively long hoses should be avoided, as they can create a cluttered layout and hinder maintenance activities.

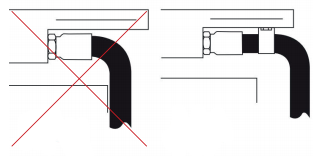

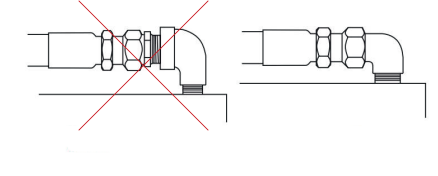

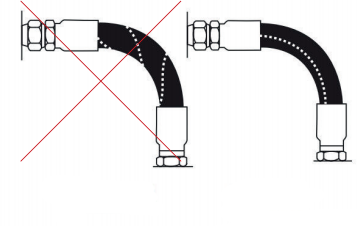

For a clean and functional installation, hoses should be properly oriented using press fittings and adapters at 45° or 90° angles.

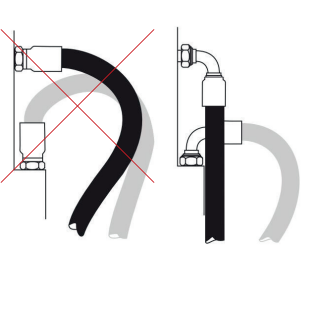

To prevent hose collapse and flow restriction, the bend radius should be kept as wide as possible.

Always refer to the hose technical specifications to ensure the minimum bend radius is respected during installation.

Exposure to high temperatures significantly shortens hose lifespan.

If proximity to heat sources cannot be avoided, an insulating protective sleeve should be applied.

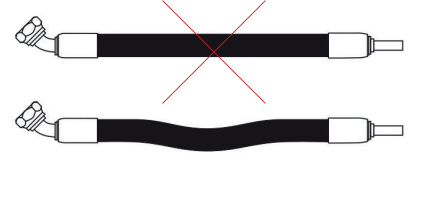

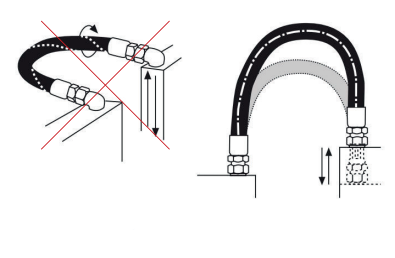

When a hose is installed in a straight line, it is advisable to allow slight slack to accommodate length changes caused by pressure during operation.

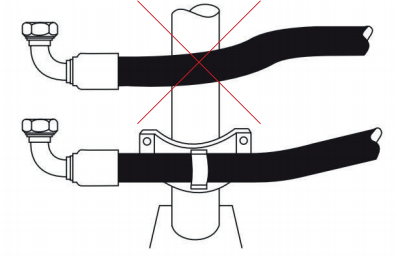

In applications involving movement, hose length must be sufficient to evenly distribute mechanical stress.

This also helps prevent abrasion damage caused by excessive rubbing or tension.

The number of threaded joints should be reduced wherever possible.

Hydraulic adapters are preferred over threaded joints, as they improve sealing reliability and simplify maintenance.

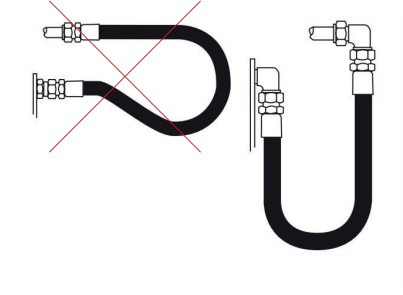

To avoid mechanical strain on the assembly, it is recommended to use elbow fittings and adapters.

This ensures a neater and more accessible installation.

Where the bend radius is below the minimum requirement, angled fittings should be used to avoid sharp bends.

Hoses must not be bent outside the movement plane of the connection port.

Proper alignment must be checked during installation, and twisting should be strictly avoided.

Pressure applied to a twisted hose can lead to failure or loosening of the connections.

Following these guidelines ensures a professional, safe, and long-lasting installation of hydraulic hose assemblies.

Proper mounting helps prevent failures, reduces wear, and makes inspection and maintenance easier.

For those already familiar with our product catalog, further details on proper hose assembly installation can be found in the Certificates and technical documents section, including our full Assembly instructions.

For more information, feel free to contact us through our online form.